PRODUCTS

Product Introduction The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line…

Mineral Ore Powder Making

20-25mm

Limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum, kaolin, bentonite, medical stone, rock phosphate, manganese ore,iron ore, copper ore, gold ore,quartz, active carbon, carbon black, ceramic, coal, etc.

Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

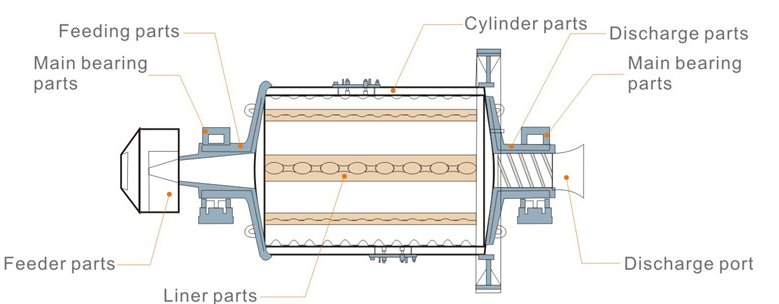

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc, and the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material.

1: Materials shall be evenly charged through quill shaft in feeding device into the first bin, which has step or waved lining with steel balls in different specifications.

2: Steel balls are taken to a certain height by centrifugal force from drum rotation and then fall. Thus it will give a heavy blow to materials, playing a role of grinding.

3: Materials after crushed in the first bin shall enter bin across single-layer diaphragm into the second, which is provided with flat lining with steel balls, to go through further grinding.

4: Powder shall be discharged from discharging grating, ending the milling process.

| Model Specification Name | MTW110 | MTW138 | MTW175 | MTW215 |

| Quantity of roller (PCS) | 4 | 4 | 5 | 5 |

| Inner diameter of ring (mm) | Ф1100 | Ф1380 | Ф1750 | Ф2150 |

| Rotary speed of main frame(r/min) | 120 | 96 | 75 | 65 |

| Max. Feeding size(mm) | < 30 | < 35 | < 40 | <50 |

| Output size (mm) | 1.6~0.045 The fineness is 0.038 | 1.6~0.045 The fineness is 0.038 | 1.6~0.045 The fineness is 0.038 | 1.6-0.055 The fineness is 0.045 |

| capacity (t/h) | 3.5~10 | 6.5~15 | 11~25 | 20-50 |

| Overall dimension (mm) | 8910×6950×9010 | 10920×9655×10227 | 12095×10023×9916 | 14500x11200x10400 |

| Total weight (t) | 18 | 28.5 | 46 | 96 |

| Name | Item | Unit | Specifications & Technical Data | ||||

| MTW110 | MTW138 | MTW175 | MTW215 | ||||

| Motor for mainframe | Model | YX3-280M-6 | YX3-315M-6 | Y2-355M2-8 | Y3-400-8 | ||

| Power | kW | 55 | 90 | 160 | 280 | ||

| Rev. | rpm | 980 | 990 | 740 | 740 | ||

| Adjustable speed motor for classifier | Model | YVP160M-6 | YVP200L2-6 | YVP250M-6 | YVP280M-4 | ||

| Power | kW | 7.5 | 22 | 37 | 90 | ||

| Rev | rpm | 1440 | 980 | 980 | 1470 | ||

| Motor for centrifugal blower | Model | YX3-250M-4 | YX3-315S-4 | YX3-315L2-4 | YX3-355L2-4 | ||

| Power | kW | 55 | 110 | 200 | 315 | ||

| REV | rpm | 1480 | 1480 | 1480 | 1480 | ||

| Accessary equipment | Bucket Elevator | Model | TH250x8m | TH315x8.5m | TH315x10.5m | TB315x11.5m | |

| Motor model | YX3-100L2-4 | YX3-112M-4 | YX3-112M-4 | YX3-160M-4 | |||

| Power | kW | 3 | 4 | 4 | 11 | ||

| Rev | rpm | 1420 | 1440 | 1480 | 1440 | ||

| Jaw Crusher | Model | PE | PE250×400 | PE250×400 | PE250×750 | PC1010 | |

| YX3-180L-6 | YX3-180L-6 | YX3-200L2-6 | YX3-315L1-6 | ||||

| Power | KW | 15 | 15 | 22 | 110 | ||

| REV | rpm | 970 | 970 | 970 | 990 | ||

| Feeder | Model | GZ2F | GZ3F | GZ4F | GZ5F | ||

| Power | KW | 0.15 | 0.2 | 0.45 | 0.65 | ||

If you have more information you would like to know, you can leave a message to us through the form below, and our staff will contact you as soon as possible

+86-371-86688302

+86 371 86688303

+86 371 86688303

+86 15736732866

No.97, Dongqing Street, National Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Looking forward to working with you