SOLUTION

Capacity: 100 t/d – 2000 t/d

Main Materials: Limestone, Clay, Gypsum, Fly Ash, Slag

Main Equipment: Cement Mill, Cement Preheater,Cement Kiln, Bag Filter, Package machine,etc

Henan Yuhong Group provide the full range service including design, manufacturing, installation. We design and manufacture equipment for new type dry method cement production line, which the capacity varies from 100t/d to 2000t/d.

The new dry type cement production line is a modern cement production method with the pre-homogenization technology and rotary kiln calcining technology as the foundation and suspension pre-heating .

Cement production line includes the following machines such as vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln, rotary dryer and packing machine and so on.

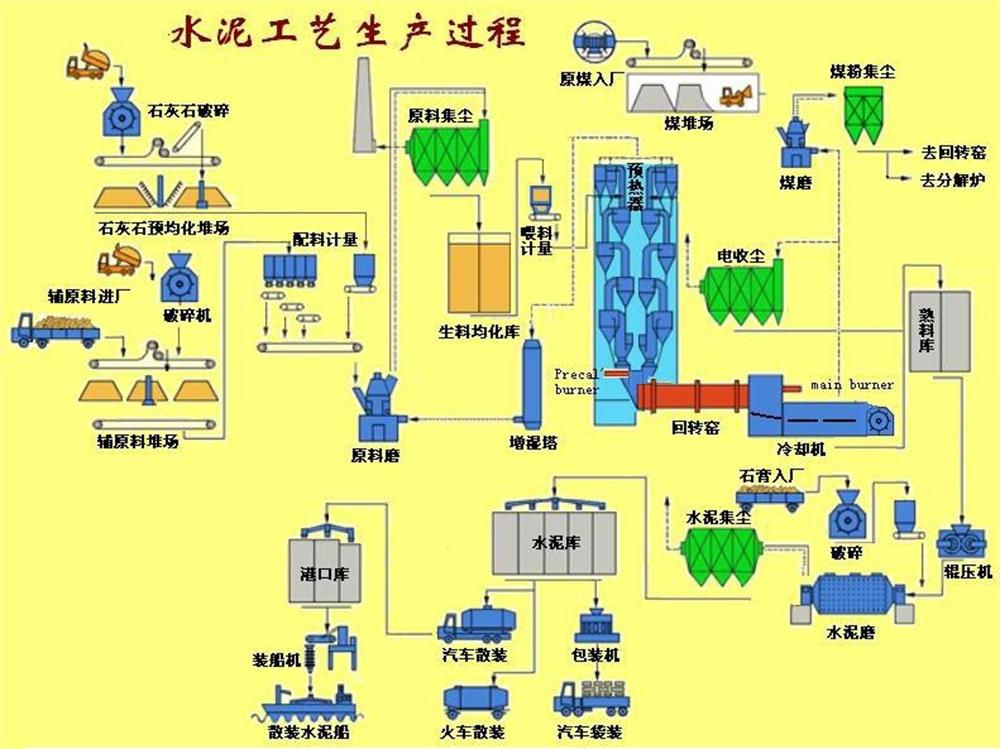

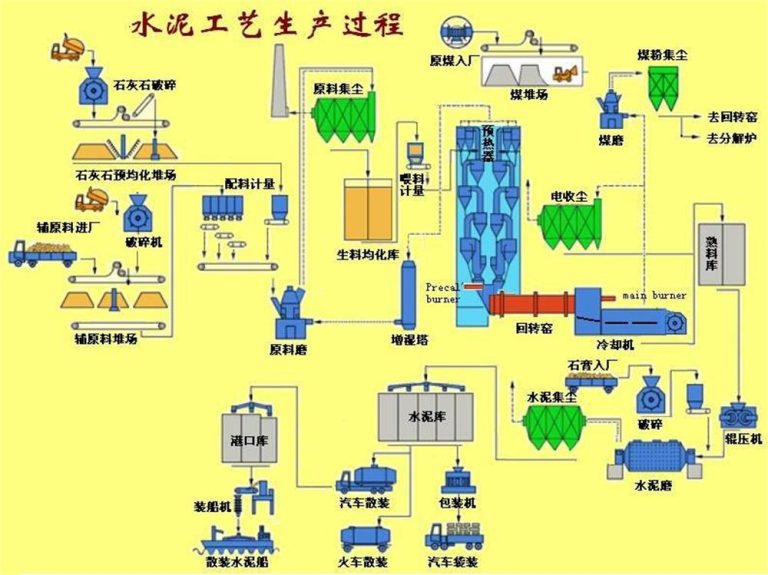

The whole production process of cement is generally as follows: homogenizing-- preparation of raw material -- raw material homogenization -- preheat decomposition -- the burning of cement clinker -- cement grinding mill -- cement packaging. In the process flow, different cement making machines should be used.

This production line makes the production of cement is highly efficient, high quality and energy saving, thus conforming to the requirements of environment production and sustainable development.

Mined limestone is delivered to the crusher for crushing by the belt conveyor, limestone after crushing ,clay, iron powder etc will be ground into powder by ball mill or vertical mill, and then transported by air delivery chute to raw meal homogenization silo for storing and further material mix. Raw meal shall get into the preheating decomposition system after homogenization where decomposition rate is about 95%, and raw meal is calcined into clinker in the rotary kiln, the formation of clinker. Clinker, gypsum and mixture is ground into qualified fineness cement in the cement mill. Powder classifier is adopted to adjust the fineness of cement, realizing energy saving production. Cement packing machine and automatic loading machine are used for bagged cement delivery, and cement bulk device for cement canning leaving factory.

Cement, coal , power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

Looking forward to working with you