PRODUCTS

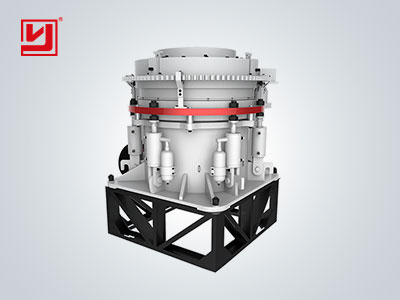

Overview The hydraulically adjusted PYG Series cone crushers are characterized by robust design and high performance. A combination of Constant Liner Performance crushing chambers and…

35-725t/h

220mm

Iron ore, copper, steel slag, slag, river stone, granite, basalt, quartz stone, diabase

metal mine, quarry, concrete batching station and glass industry

The hydraulically adjusted PYG Series cone crushers are characterized by robust design and high performance. A combination of Constant Liner Performance crushing chambers and high motor power give these crushers very high capacity. the PYG Series Hydraulic Cone Crusher combines the highest crushing efficiency and end product quality with the lowest per ton production costs.

Under the leading role of eccentric sleeve, the movable cone of the high-efficiency hydraulic cone crusher does rotary and pendulum movement which drives the broken walls squeeze and twist the raw material between the rolling ace tabular wall and it. According to laminated theory, the raw material is crushed and polished following their own texture by the force from different directions. Stable aggregate are produced finally. The eligible raw material falls down from the gap of the broken wall. The others will be kept crushing until it reaches the desired size.

| Type | Model | Chamber Type | Diameter of Large End of Crushing Cone (mm) | Adjustable Range of Discharge Opening (mm) | Max Feed Size | Capacity (t/h) | Motor Power (kw) | Weight (kg) | Dimension (L×W×H)(mm) |

|---|---|---|---|---|---|---|---|---|---|

| Ф900 | PYGB-0913 | Standard fine type | 950 | 14-38 | 110 | 130-250 | 160 | 17000 | 2007×2225×1950 |

| PYGB-0916 | Standard medium type | 18-38 | 132 | 145-250 | |||||

| PYGB-0921 | Standard coarse type | 22-38 | 178 | 155-250 | |||||

| PYGD-0907 | Short coarse type | 8-25 | 60 | 80-220 | |||||

| PYGD-0909 | Short head medium type | 10-25 | 76 | 90-220 | |||||

| PYGD-0912 | Short head coarse type | 12-15 | 100 | 120-220 | |||||

| Ф1100 | PYGB-1114 | Standard fine type | 1100 | 16-45 | 115 | 180-445 | 220 | 18500 | 2520×2620×2400 |

| PYGB-1121 | Standard medium type | 20-45 | 180 | 200-445 | |||||

| PYGB-1124 | Standard coarse type | 26-45 | 200 | 230-445 | |||||

| PYGD-1107 | Short coarse type | 8-25 | 60 | 120-220 | |||||

| PYGD-1110 | Short head medium type | 12-25 | 82 | 120-220 | |||||

| PYGD-1112 | Short head coarse type | 14-25 | 105 | 120-220 | |||||

| Ф1400 | PYGB-1415 | Standard fine type | 1400 | 16-50 | 130 | 225-620 | 315 | 29700 | 3106×3170×2945 |

| PYGB-1420 | Standard medium type | 22-50 | 170 | 270-620 | |||||

| PYGB-1433 | Standard coarse type | 26-50 | 280 | 300-620 | |||||

| PYGD-1408 | Short coarse type | 8-25 | 68 | 115-370 | |||||

| PYGD-1411 | Short head medium type | 10-25 | 90 | 140-370 | |||||

| PYGD-1414 | Short head coarse type | 12-25 | 115 | 180-370 | |||||

| Ф1500 | PYGB-1518 | Standard fine type | 1500 | 19-50 | 152 | 320-725 | 400 | 38800 | 3405×3480×3196 |

If you have more information you would like to know, you can leave a message to us through the form below, and our staff will contact you as soon as possible

+86-371-86688302

+86 371 86688303

+86 371 86688303

+86 15736732866

No.97, Dongqing Street, National Hi-Tech Development Zone, Zhengzhou City, Henan Province, China

Looking forward to working with you